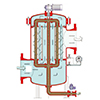

CRAF Series Automatic Back-Flushing Filters

Introduction

CRAF series automatic backflushing filter is a new generation self-cleaning filtration system independently designed by Xing Wei Hui Da company,filter vessel are designed and manufactured according to the GB / ASME Steel Pressure Vessel Standard.

CRAF series automatic backflushing filter is integrated with a number of wedge slotted tube filter elements,it has the advantages of compact structure,large filtration area,small space,low pressure drop,less back flushing frequency as well as continuous automatic on-line filtration and cleaning,super high flowrate up to 7000m3/h in single filter,Its the advanced solution for the self-cleaning filtrationof water and low viscous liquids.

CRAF series automatic backflushing filters are widely used in iron and steel,metallurgy,electric power,papermaking, chemical,petroleum,pharmaceutical,food,mining,urban water supply and other fields.

Working Principle

CRAF series automatic backflushing filters main components include filter housing, filter elements, gear-motor, photoelectric positioning sensor, cleaning arm, drain valve, differential pressure sensor and control system. Please click on the link to view the working principle of video

Technical Features And Adventags

■ Continuous automatic online filtration, no flow interruption when back flushing, reducing downtime and maintenance cost

■ Large filter area, low surface flow velocity, low pressure drop, accuracy fine filtration, less back flushing frequency

■ Metal Wedge Tubes high performance filter element, accurate and uniform slot, efficient back flushing, high strength structure, long service life over 10 years

■ Impulse back flushing one by one, high back flushing intensity, less time consuming, less back flushing water consumption

■ Water flows in the filter element from both ends, which increases the flux, allows the water flow freely to reduce the clogging and avoids clogging at one dead end of the element

■ Compact design, super high flowrate in single filter, saving installation space and construction costs prominently

■ High integration without many valves, fittings and seals, high reliability and low running cost

■ Vertical and Horizontal filter housings configurations and flexible Inlet and Outlet flange orientations are offered for most sizes, allowing custom arrangements to accommodate installation requirements.

■ High reliability in automatic control system , friendly Interface, easy to adjust the running mode to fit the service condition

Technical Specifications

| ■ Filter Fineness:5-3000μm | ■ Flow Rate:4.5-7000m3/h |

| ■ DES.PRES (MPa):10bar(STD) / 16bar / 7bar | ■ DES.TEMP :90℃ |

| ■ Housing Material:SS304 / SS316L / CS | ■ Filter Element Material:SS304 / SS316L |

| ■ Driving Device:Gear Motor | ■ Arm Material: SS316L |

| ■ Viscosity (cp):1-40 | ■ Power Supply:AC380 & 50HZ |

| Cleaning Start Mode | |

| ■ Difference Pressure Control Differential pressure indicator detects the pressure drop at both sides of the filter element reaches the set MAX allowed, The control system starts the cleaning action |

|

| ■ Time Control Set the time of the time module in the control system and perform the cleaning action periodically. When the differential pressure start and time start simultaneously, differential pressure start priority |

|

| ■ Manual Operationl The manual switch on the control panel can immediately start the cleaning procedure, which is usually used when the equipment is installed and debugged, the system maintenance or other needs |

|

Model Technical Parameters

Model |

Dimensions mm | Filtration area cm2 |

Flow Rate m3/h |

|||||||||

| L | L1 | L2 | L3 | L4 | H | H1 | H2 | H3 | H4 | |||

| CRAF2 | 218 | 165 | 218 | 60 | 246 | 1010 | 918 | 607 | 220 | 100 | 2140 | 4.5 ~28 |

| CRAF4 | 223 | 171 | 223 | 102 | 246 | 1330 | 1015 | 801 | 276 | 115 | 3810 | 25 ~112 |

| CRAF6 | 302 | 241 | 302 | 120 | 260 | 1427 | 1147 | 894 | 300 | 117 | 6190 | 90 ~254 |

| CRAF8 | 362 | 298 | 362 | 160 | 299 | 1595 | 1310 | 1058 | 400 | 179 | 8250 | 200~450 |

| CRAF10 | 365 | 298 | 365 | 152 | 298 | 2091 | 1865 | 1301 | 399 | 170 | 12500 | 400~600 |

| CRAF12 | 424 | 349 | 424 | 160 | 260 | 2299 | 1953 | 1446 | 493 | 185 | 18750 | 550~860 |

| CRAF16 | 549 | 406 | 549 | 203 | 280 | 2454 | 2102 | 1595 | 600 | 221 | 37500 | 810~1698 |

| CRAF20 | 620 | 464 | 620 | 254 | 280 | 2497 | 2121 | 1615 | 598 | 200 | 55760 | 1500~2450 |

| CRAF24 | 697 | 584 | 697 | 300 | 280 | 2721 | 2326 | 1825 | 674 | 214 | 89100 | 2000~3600 |

| CRAF28 | 795 | 645 | 795 | 794 | 2901 | 2506 | 1937 | 700 | 223 | 106100 | 3000~5000 | |

| CRAF36 | 1035 | 756 | 1035 | 300 | 3758 | 3345 | 2647 | 1000 | 215 | 180700 | 4500~7500 | |

| Note: ■ The decisive factors of filter flow are filter element type, filter fineness, liquid viscosity etc. ■ Filtration flow is not the only factor in determining the selection, the amount of pollutants, operating pressure drop, etc. are important factors selection |

||||||||||||

APPLICATIONS

■ Applicable Industries:Chemical and petrochemical, pulp and paper,Electricity and energy, Iron and steel,Mining and metallurgy,Pharmaceutical and biology,Food and beverages, Automobile industry, Water treatment,machinery manufacturing,irrigation etc

■ Typical Applicable Liquids:Reservoir water, freshwater, Groundwater, seawater, pond water, cooling circulating water, freezing water, high and low spraying water, squirt water, heat exchanging water, sealing water, bearing cooling water, recycled process water, machining coolant, cleaning agents, cleaning water, etc..

Download